FAQ

Important information for laser cleaning

Introduction

We are often asked for information about cleaning with laser. This document has been created to answer frequently asked questions and as a resource for anyone considering doing business with our Narran ROD laser cleaning systems. Laser cleaning is an emerging technology with huge commercial and industrial applications and a large number of potential customers.

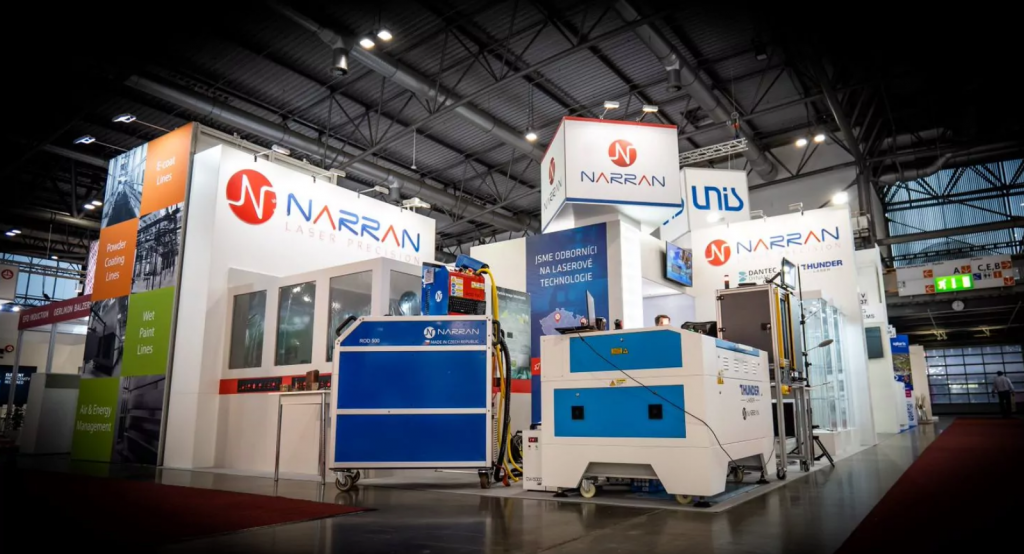

About Narran company

Narran is a team of motivated people with passion for laser technology. We are a Czech company that was founded in 2013 to develop and manufacture our own laser systems, automation, build single-purpose machines and sell laser equipment mainly from foreign EU manufacturers. In our development department we have experts with degrees in nuclear physics focused on lasers, electrical engineers, mathematicians and physicists. This solid foundation is mainly underwritten by the development of cleaning lasers – design, implementation, continuous improvement, but also other laser projects (designing single-purpose machines, robotic applications, automation, designing solutions for customers). We can create a complete solution for any laser application from the initial customer idea to finished mass production.

How does laser cleaning work

Laser cleaning uses concentrated laser radiation to evaporate impurities from the layer. Ultra-short laser pulses (μs-ms) are applied to the contaminants, generating heat and heat-induced pressure – the high temperature inside the material creates high pressure, which causes it to vaporize. Laser cleaning is a non-contact, non-abrasive method and is therefore very gentle on the original material. Laser cleaning produces almost no waste material as most of the impurities are evaporated, and due to the high efficiency of the laser resonators used, the cleaning process has very low operating costs (Laser cleaning – cost/performance/return). Since the course of interaction of the laser radiation with the material is material dependent, it is possible to adjust the cleaning parameters so that the substrate remains undamaged after cleaning.

FAQ

What are the benefits of laser cleaning?

- It does not damage the underlying material.

- It has the lowest operating costs of all the industrial cleaning methods (less than 1EUR/hr).

- Easy operation and intuitive user interface.

- Eco-friendly – no use of any added material or chemicals.

- Quick return of your investment.

- Speed and efficiency.

- Fast implementation.

- Products little to no additional waste.

What to consider before buying a cleaning laser?

Price: the price is primarily based on the performance of the system, country of origin, service conditions, quality of the resonator. From our own experience, we recommend to try to avoid the cheapest laser systems, as they usually have a number of problems associated with them, the biggest of which was that they contained a different resonator (laser source, the most important and expensive part of the laser system) than advertised. Before purchasing a system, check the service conditions of each company to ensure that you are properly educated on laser system operation, maintenance, and service.

Type of laser cleaning system: there are significant differences between laser cleaning systems, especially between continuous and pulsed laser systems. CW (continuous wave) are significantly cheaper but have a much smaller range of applications (only rust from selected metals, also they are significantly less gentle on the underlying material).

What are the most suitable applications for laser?

Rust/oxidation removal – the best known advantage of laser cleaning. Rust can be removed from everything from a small metal nut to large industrial machinery using a laser.

Coating removal, surface preparation – laser cleaning is one of the best preparation processes before any welding, soldering, bonding or new coating process.

Degreasing/cleaning of industrial moulds – the most commonly used method in the process and manufacturing industries to remove dirt, moisture and other contaminants.

Restoration – laser cleaning is particularly effective in restoring deteriorated stone or, rarely, wooden objects, but it is recommended to check beforehand whether cleaning may cause adverse effects.

Selective cleaning – It is not always necessary to clean the entire surface, the laser is also the optimal choice for cleaning individual darkened parts.

What kind of laser do I need to start cleaning?

Lasers with power from 50 to 1000W are capable of the same cleaning results but they differ greatly in the time it takes them. It is therefore recommended to choose laser by the size of the surface being cleaned.

Lasers can be divided into three categories by their power:

Low power (50W – 100W)

Medium power (200W-500W)

High power (1000W)

What are the operating costs of laser cleaning?

Our lasers are very efficient and environmentally friendly machines (possibility of obtaining ISO 14020 and ISO 14024). You do not need any additional materials for the cleaning process (abrasives for blasting, gases, dry ice pellets…), the efficiency of laser resonators is up to 50% and so the electricity consumption is up to 3000W / hour. Therefore, the cost per hour of cleaning should not exceed 1,5EUR/hour (wear of optics, electricity, preventive service).

For more information see our article: Laser cleaning – cost/performance/return

How is it possible that the laser removes dirt and does not damage the substrate?

Properly selected and set laser, both hardware and software-wise, is absorbed in the dirt (rust, oil, paint, grease, adhesives, separators) where the laser ablation occurs, i.e. removal of impurities, but does not have enough energy to damage the substrate (steel, stainless steel, aluminum, metals, copper, stone, sandstone, granite, marble…), therefore it is especially suitable for cleaning molds, tools, car parts, machines and also restoration in general.

How do you operate a laser?

The laser is controlled by a large clear touch screen. The user can easily select, save and name individual tasks and parameters for easy repeat cleaning. It is now also possible to adjust the main functions via the ergonomic process head even during the cleaning itself. The system also allows various options of login and rights for increased security and process repeatability.

Is laser cleaning safe?

ROD series mobile cleaning lasers fall into category IV, so it is necessary to follow certain rules for safe use. Our lasers usually have a wavelength of 1064-1070nm, this is an area of infrared radiation, i. e. invisible to the human eye. Therefore, it is necessary to wear special goggles in the first place. Other rules are specified according to EN 60825-1 which we will of course guide you through and train accordingly.

Laser safety glasses

We supply the highest quality laser safety glasses currently on the market. All of the variants we offer do have CE certification.

CO2 laser protection glasses for CO2 cutting, marking and engraving lasers

YG2 laser protection glasses for Nd:YAG cutting, marking and engraving lasers

YG3 laser protection glasses for Nd:YAG cutting, marking and engraving lasers

YPL laser protection glasses for YPL, optical path adjustment

DBY laser protection glasses for ND-YAG systems + II. harmonic

Portable security barriers

Portable laser security barriers are designed to increase safety when maintaining laser equipment.

Protects against laser radiation and meets the following certifications and standards: ANSI, CE and NFPA-701

Will laser price go lower in the future?

We do not expect the price of laser systems to fall. The knowledge needed to manufacture components and systems is highly specialized and there is no room for any significant price jumps.

How long service life does a laser have?

The life service of a resonator, which is the source of a laser is more than 15 000 hours of use.

How does the service work?

ROD cleaning machines are designed to be virtually maintenance-free; an average user takes care of keeping the optical parts of the laser clean and adding clean water to the cooling. Preventive service is not required by Narran on these machines and the laser can be used for nonstop operation.

Can I see and test laser before purchase?

Absolutely, you just need to make an appointment at our headquarters in Prague 9 and ideally bring samples of what you want to clean. You can find the address and contacts here.

Why are some other manufacturers cheaper, especially ones from China?

A detailed comparison between our laser and the Chinese laser is described in the case study:

Case study: comparison of Czech and Chinese lasers

When two do the same thing, it isn’t necessarily the same thing, laser is not a cheap matter, so you should make sure to compare two same machines before purchasing a new device, same or similar components and of course – the same services (warranty, service, service life of the resonators – their manufacturer, technological experience and ergonomic properties). You should pay a visit to the distributor, try the machine yourself and test it. If it is your first-time laser experience, we would be more than happy to make a free comparison for You.

What is the price of a cleaning laser?

Our laser cleaner price range begins at 30 000 EUR for 50W system up to 300 000 EUR for 2000W cleaner.

How long is the hose, cable, fiber or how is it called?

That depends on the system, for lower outputs such as 50, 200 and 300W the limit is 10m, usually 10m for 500W it is possible to build a system with up to 50m fiber.

How wide is the laser beam?

The beam itself is a small point, which is further worked with the use of mirrors, therefore it can be scattered into any shape (lines, circles, rectangles, ellipses, etc.). The width of the shot, therefore, depends on the size we set, then on the optics used, due to the smooth manual move during the cleaning process we usually choose a width of 8cm. It is usually possible to choose between approximately 1-10cm, for special applications up to approximately 30cm.

How does the service work?

ROD cleaning machines are designed to be virtually maintenance-free; an average user takes care of keeping the optical parts of the laser clean and adding clean water to the cooling. Preventive service is not required by Narran on these machines and the laser can be used for nonstop operation.

What will happen if a laser beam runs over my hand?

As part of the safety of working with laser equipment, it is of course recommended to wear protective gloves when cleaning. If you decide to clean the laser without gloves and accidentally run the laser over your hand, several factors matter: if you hit the focus distance you will burn your hand, if you are out of focus you will only feel heat. The laser is partly reflected, partly absorbed in the material, or it can also pass through the material. Of course, it also depends on the power of the laser.

Can a laser remove rust?

Cleaning rust with a laser is one of the most, if not the most efficient and effective methods of removing rust. Rust, varnish, oil and other contaminants will not resist laser cleaning methods.

What is HS CODE for ordering a laser?

HS code for lasers is 90132000 – Lasers, laser, diodes. Lasers (excl. laser diodes)