Focused laser beam technology

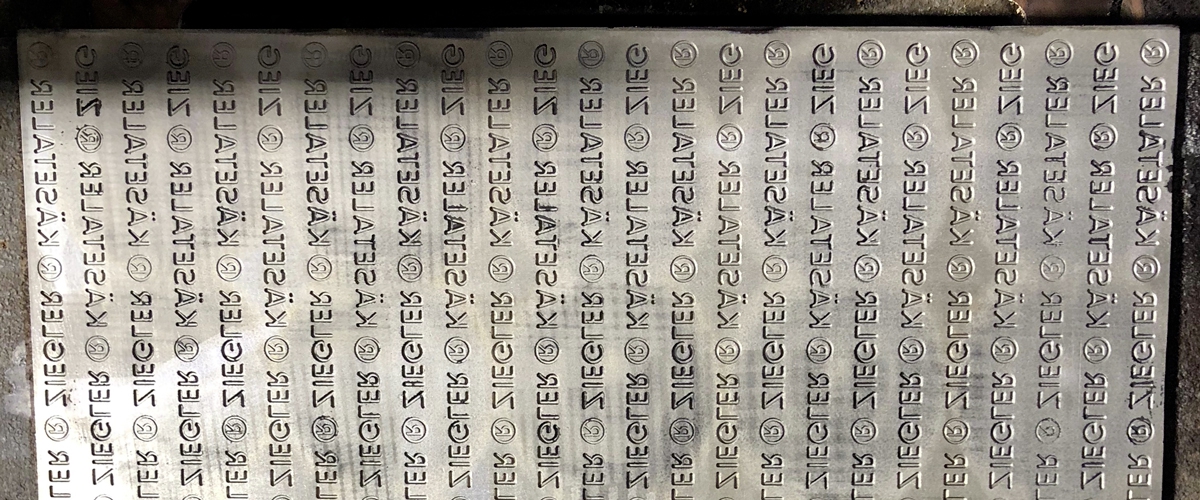

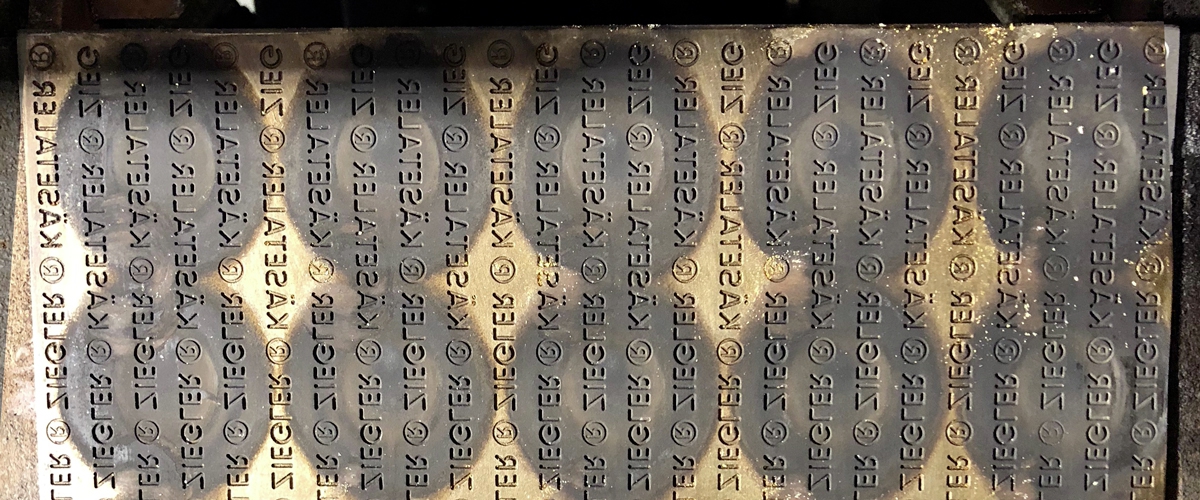

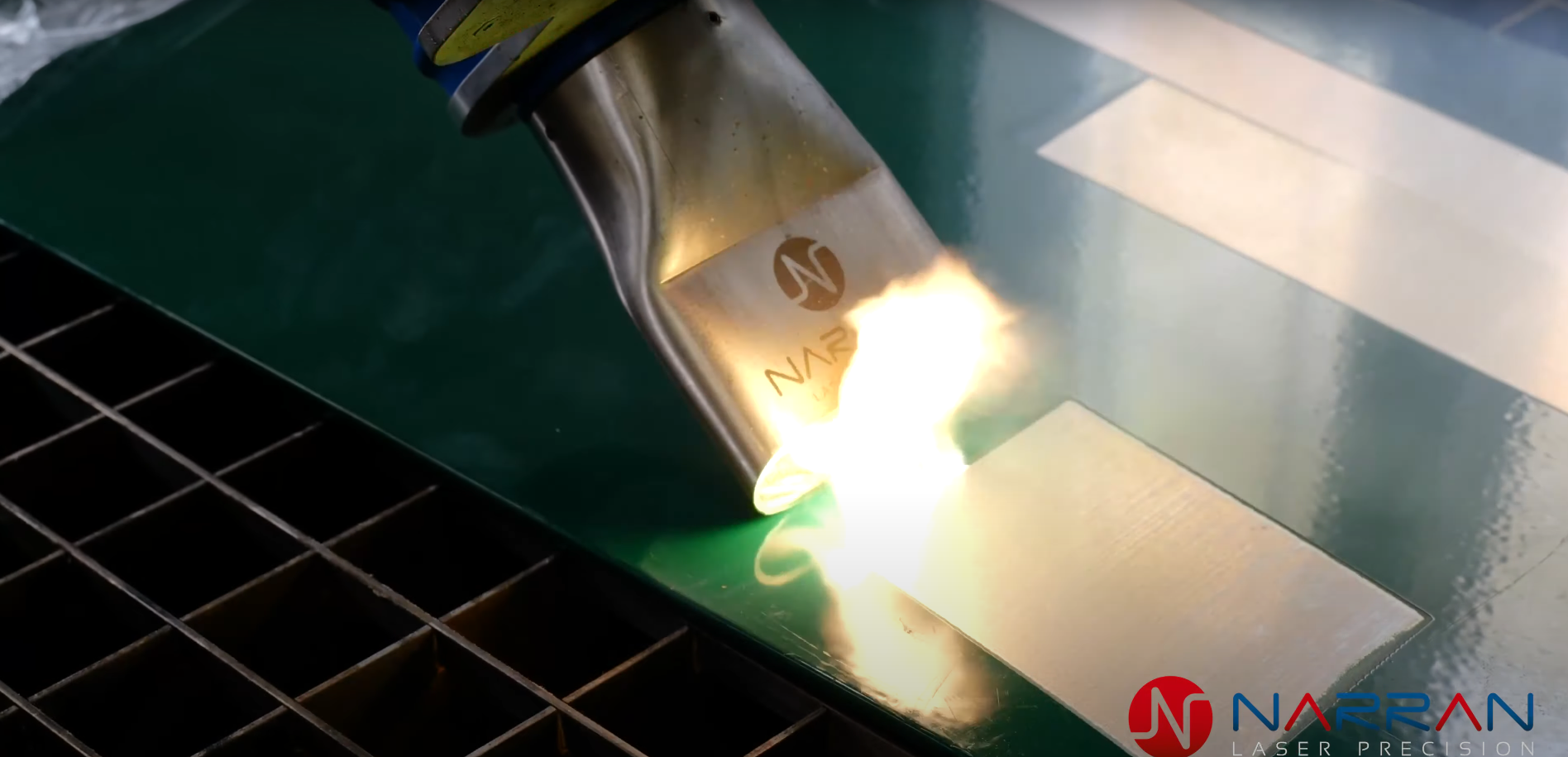

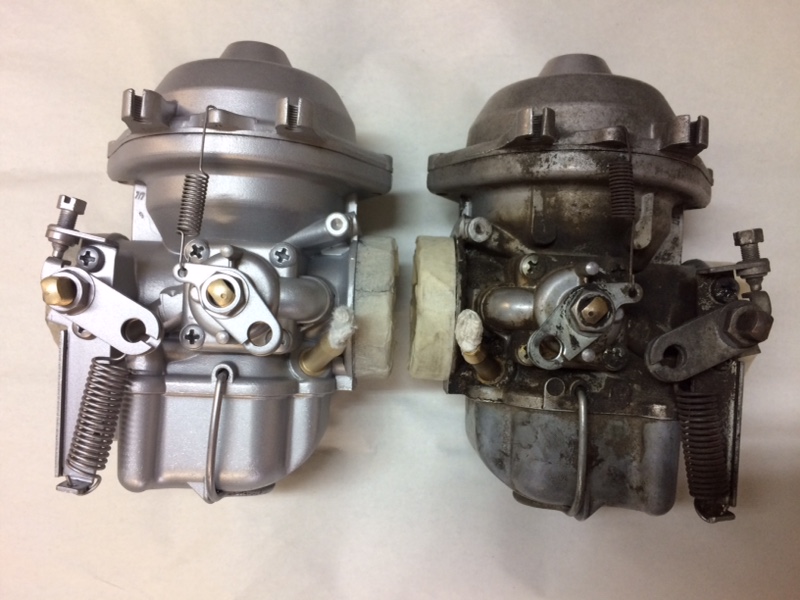

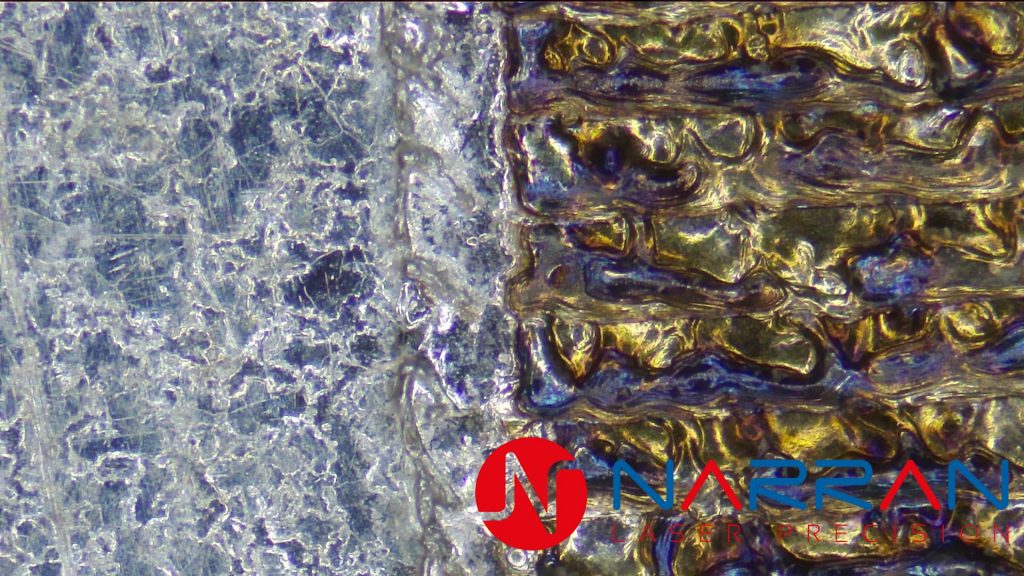

Laser cleaning works on the principle of laser ablation, by which individual molecular bonds are broken down and released from the surface.

Thanks to high intensity laser pulses of a few nanoseconds, the surface impurities are heated very quickly, which causes evaporation, but also creates local explosions that remove the impurities from the surface.

Our lasers clean and remove

- Fats

- Separators

- Rust and oxidation

- Paint

- Ink

- Oil

- Dried polyurethane foam

- Lacquers and adhesives

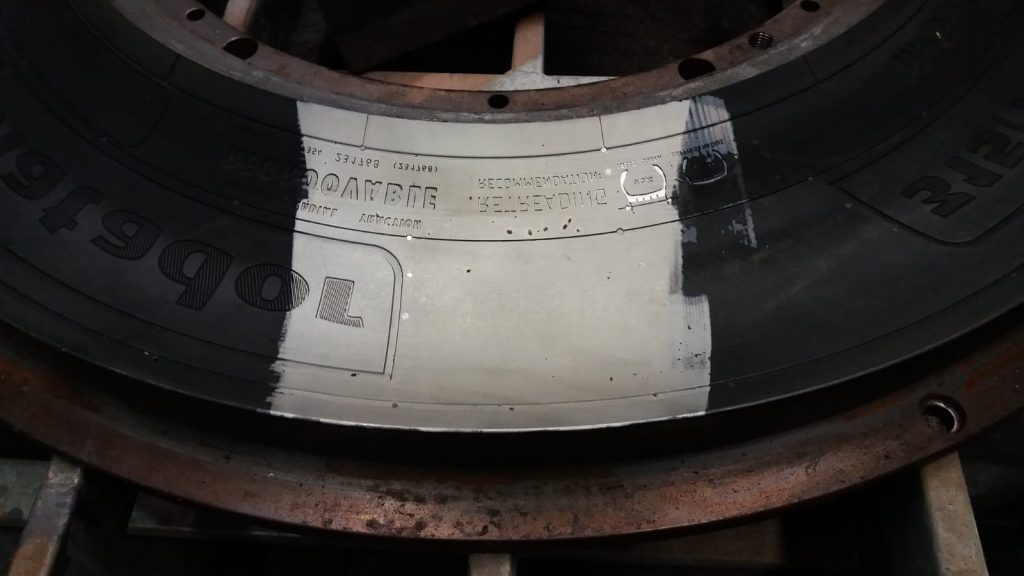

- Natural and synthetic rubbers

- Grease

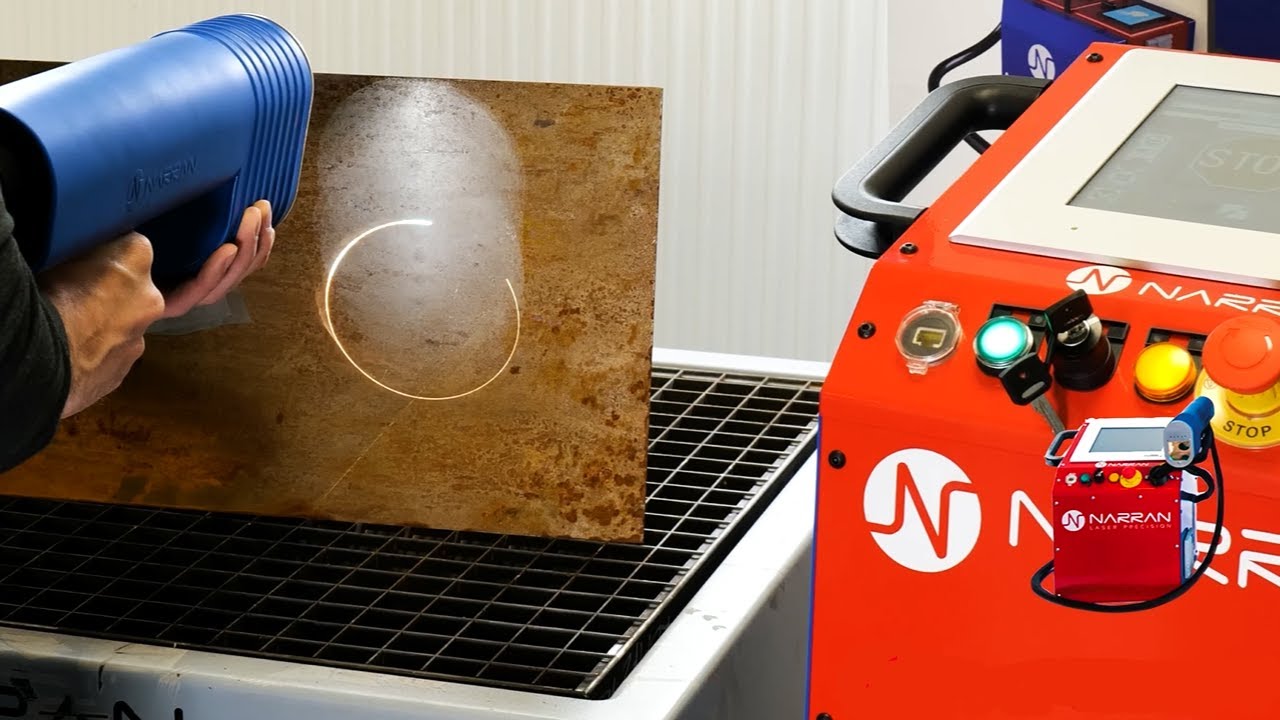

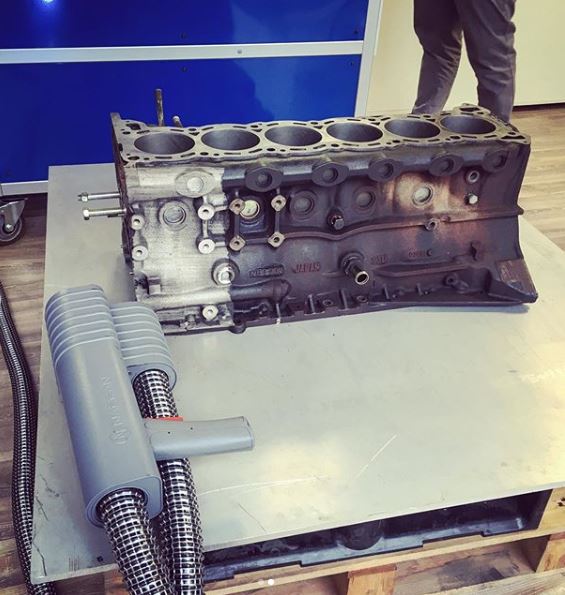

Almost no waste material is produced by laser cleaning because most of the impurities evaporate, and thanks to the high efficiency of the laser resonators used, the cleaning process has very low operating costs. Unlike other methods, only a 230 V power supply is required for laser cleaning. Laser cleaning is a non-contact, non-abrasive method that is very gentle on the underlying surface of the material. As the effect of the laser radiation on the material is material dependent, the cleaning parameters can be set to ensure that the underlying surface remains undamaged after cleaning.

How the cleaning works